Ketika perdagangan global terus berkembang, perusahaan-perusahaan di seluruh dunia menghadapi tantangan yang meningkat ketika mengimpor produk teknologi tinggi ke pasar lokal. Negara seperti India dan Indonesia telah menerapkan peraturan ketat tentang impor yang sepenuhnya dirakit, terutama untuk produk yang berasal dari Tiongkok. Pada saat yang sama, faktor geoptikal, termasuk ketegangan jual beli AS-Tiongkok, telah menyebabkan negara seperti Meksiko menjadi pusat penting untuk komponen manufaktur dan perakitan, terutama untuk produk yang dialokasikan untuk ekspor ke Amerika Utara.

Perangkat teknologi tinggi seperti layar interaktif Qtenboard tidak menimbulkan tantangan jual beli global ini. Solusi layar terakit sepenuhnya, yang ketika kunjungi pasar, semakin praktis. Sebagai gantinya, Semi mengetuk (SKD) dan solusi yang benar-benar mengetuk (CKD) menjadi pilihan untuk perusahaan, menawarkan fleksibel, hemat biaya, dan cara skalabel untuk menempatkan produk di berbagai wilayah. Artikel ini memberikan tampilan komprehensif di solusi SKD dan CKD dari Qtenboard, termasuk proses perakitan, keuntungan unik, pertimbangan logistik, perbandingan biaya, dan rekomendasi praktis untuk bisnis yang ingin mengoptimalkan perakitan lokal dan efisiensi rantai pasokan.

SKD (Semi mengetuk) dan CKD (benar-benar mengetuk) adalah dua strategi perakitan umum dalam industri tampilan interaktif. Qtenboard telah mengembangkan kedua pendekatan untuk memenuhi berbagai kebutuhan regional dan pasar. Kedua strategi melibatkan peroduk yang sepenuhnya dirakit menjadi komponen yang lebih kecil dan dapat dibawa, namun mereka berbeda dalam hal tingkat pembongkaran, kompleksitas teknis, dan persyaratan perakitan lokal.

Di SKD, sebagian besar komponen mainboard sudah dirakit di pabrik. Hanya perakitan minor yang diperlukan di tujuan, seperti melampirkan papan utama ke panel tampilan, menghubungkan suplai daya, dan mengintegrasikan modul sentuh. SKD ideal untuk perusahaan dengan keahlian teknis terbatas, ruang perakitan yang lebih kecil, atau operasi berskala lebih kecil. Memungkinkan perusahaan untuk menghemat bea masuk, mengurangi waktu perakitan, dan memasuki pasar dengan lebih cepat.

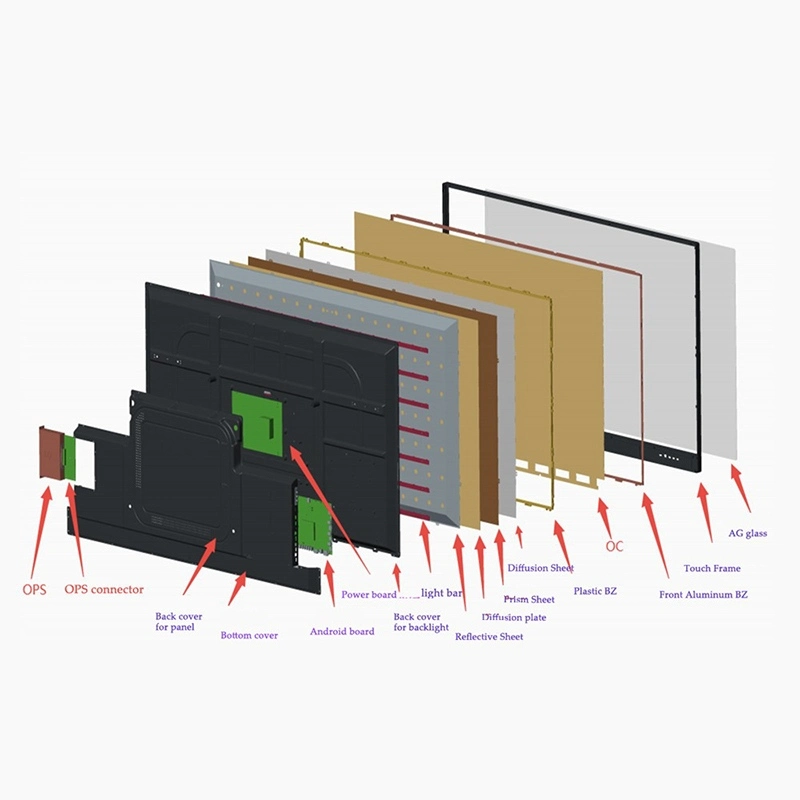

CKD lebih maju dengan mengirimkan setiap komponen secara terpisah. Ini termasuk panel tampilan, sistem lampu latar, reflektor, Diffuser, modul papan utama, komponen catu daya, dan aksesori lainnya. Perakitan lokal membutuhkan jalur produksi khusus, alat khusus, dan tenaga kerja yang terampil. CKD cocok untuk distributor besar atau produsen yang ingin kendali penuh atas proses perakitan, menyesuaikan produk ke standar regional, atau mengintegrasikan pencitraan lokal.

Singkatnya, SKD menyediakan solusi entri pasar yang lebih cepat dan lebih hemat biaya, sementara CKD menawarkan fleksibilitas maksimum, potensi kustomisasi penuh, dan tambahan nilai yang lebih tinggi. CKD memungkinkan bisnis untuk mengoptimalkan produk untuk pasar lokal, mematuhi peraturan regional, dan mempertahankan standar berkualitas tinggi.

Proses perakitan SKD dan CKD sangat berbeda:

Sebagian besar komponen inti adalah pra-dirakit di pabrik Qtenboard. Pada saat tiba, hanya mainboard dan beberapa koneksi perifer yang perlu diintegrasikan. Proses perakitan secara umum meliputi:

Metode ini efisien, membutuhkan ruang minimal, dan melibatkan kompleksitas teknis yang relatif rendah.

CKD membutuhkan perakitan lokal yang komprehensif. Setiap komponen, dari panel tampilan hingga kabel internal dan modul pendukung, dikirim secara terpisah. Proses perakitan meliputi:

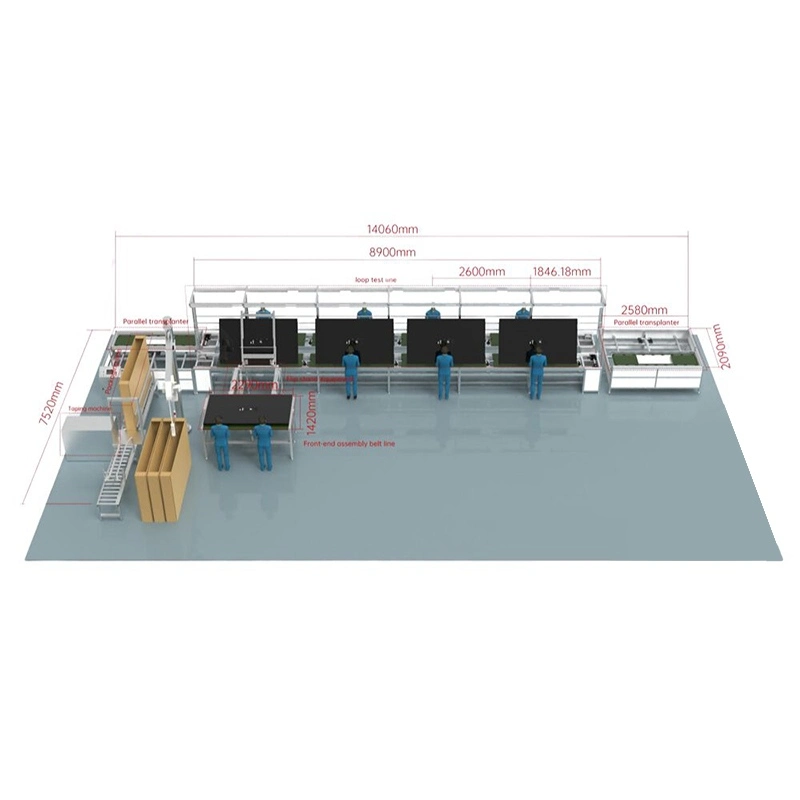

Rakitan CKD biasanya berlangsung di pabrik lokal mulai dari 600 hingga 3,000 m², dengan kapasitas produksi tergantung pada ukuran tenaga kerja:

| Ukuran tenaga kerja | Kapasitas produksi |

|---|---|

| Tim 10 orang | ~ 16 unit/hari |

| Tim 20 orang | ~ 32 Unit/hari |

| Tim 30 orang | ~ 100 unit/hari |

Setiap langkah mengikuti prosedur operasi standar terperinci (SOP) yang mencakup perakitan, pemasangan, pengujian, dan inspeksi, memastikan bahwa setiap tampilan interaktif Qtenboard bekerja sempurna di ruang kelas, ruang rapat, atau ruang publik.

Salah satu keunggulan yang paling menonjol dari SKD dan CKD adalah pengurangan bea masuk yang signifikan. Di pasar tarif tinggi seperti India atau Indonesia, mengimpor komponen bukan display yang sepenuhnya dirakit memungkinkan perusahaan untuk menghindari tarif berat, mengurangi biaya total 40%.

Pemerintah sering memberikan insentif untuk operasi perakitan lokal, termasuk pelanggaran pajak, subsidi, atau prosedur peraturan yang disederhanakan. SKD/CKD memungkinkan perusahaan untuk memanfaatkan keuntungan ini, membangun kemampuan produksi lokal, dan mempercepat waktu-ke pasar. Perakitan lokal juga memungkinkan bisnis untuk menyesuaikan fitur produk, konfigurasi perangkat lunak, dan sertifikasi untuk memenuhi persyaratan regional.

Pengiriman yang dibongkar secara signifikan mengurangi volume pengiriman dan berat, menurunkan biaya transportasi. Pemanfaatan kontainer yang lebih baik dan penanganan yang disederhanakan juga mengurangi emisi karbon dan mendukung inisiatif ketahanannya.

Solusi SKD dan CKD memungkinkan perusahaan untuk secara cepat menanggapi perubahan permintaan, menyesuaikan produk sesuai dengan kebutuhan klien, dan menyesuaikan inventaris secara lokal tanpa sepenuhnya bergantung pada pemasok luar negeri.

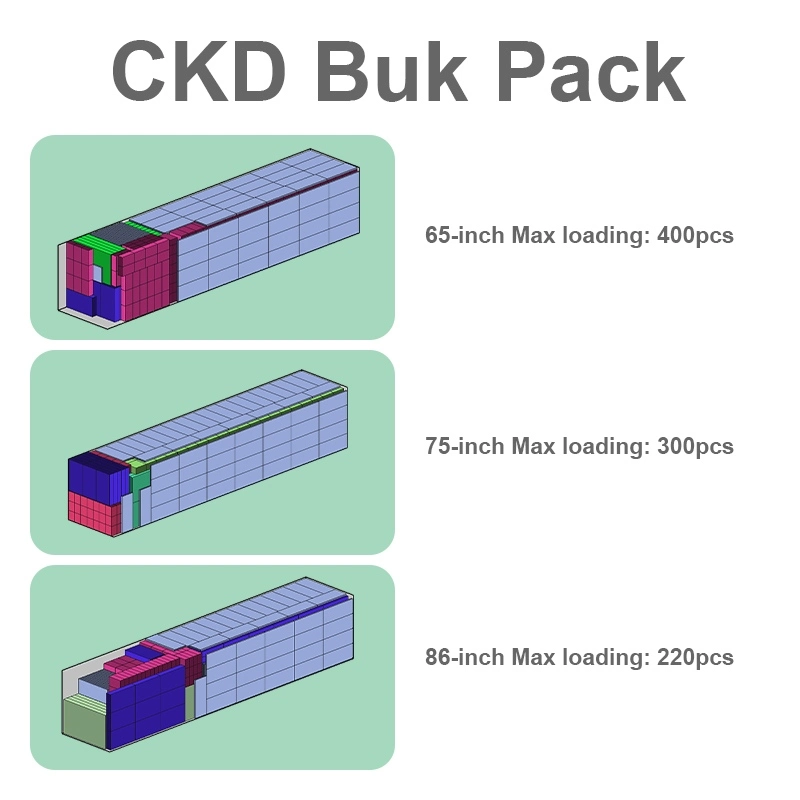

Pengiriman Qtenboard display dalam bentuk SKD/CKD memaksimalkan pemanfaatan kontainer:

Tampilan 65 inci: ~ 300 unit per 40HQ kontainer

Tampilan 75 inci: ~ 300 unit per 40HQ kontainer

Tampilan 86 inci: ~ 220 unit per 40HQ kontainer

Pengiriman yang dibongkar mengurangi volume pengemasan, meningkatkan unit per kontainer, biaya pengiriman yang lebih rendah, menyederhanakan prosedur bea cukai, dan mengurangi risiko penanganan.

Meskipun SKD/CKD menawarkan banyak keunggulan, perusahaan harus mempertimbangkan:

Dengan mitra berpengalaman, tantangan ini dapat dikelola secara efektif, menyeimbangkan penghematan biaya dengan kualitas dan fleksibilitas.

Di seluruh wilayah seperti India, Asia Tenggara, dan CIS, banyak mitra Qtenboard mengadopsi solusi SKD/CKD untuk mendukung pertumbuhan bisnis. Mitra ini biasanya memiliki pengalaman pasar yang luas, keahlian teknis, dan sumber daya yang cukup untuk mengelola proses perakitan, koordinasi rantai pasokan, dan kontrol kualitas, secara efektif mengurangi risiko yang biasanya terkait dengan solusi yang dibongkar.

Bagi perusahaan yang ingin mengurangi biaya, mengoptimalkan logistik, dan memanfaatkan kemampuan perakitan lokal, solusi Qtenboard SKD/CKD memberikan pendekatan yang fleksibel, terukur, dan berkualitas tinggi.

Hubungi Qtenboard sekarang untuk menjelajahi strategi SKD/CKD yang disesuaikan yang dirancang untuk pasar tertentu dan kebutuhan operasional Anda.

Klik untuk membaca rincian produk dan mempelajari tentang fitur fungsional dan kinerja fisiknya.

📖Baca produk